In the fields of architectural decoration, acoustics, and insulation engineering, fiberglass, mineral wool, and rock wool ceilings are widely used in various public spaces and residential scenarios due to their dual nature of decoration and functionality. All three belong to the category of fiber ceilings, but they differ significantly in terms of raw material composition, performance emphasis, and applicable scenarios. This article will comprehensively analyze these three types from dimensions such as core definition, component characteristics, key performance, applicable fields, and purchase tips, to help with precise selection.

1. Fiberglass Ceiling: The Preferred Lightweight and Environmentally Friendly Acoustic Decorative Option

1.1 Core Definition and Raw Material Composition

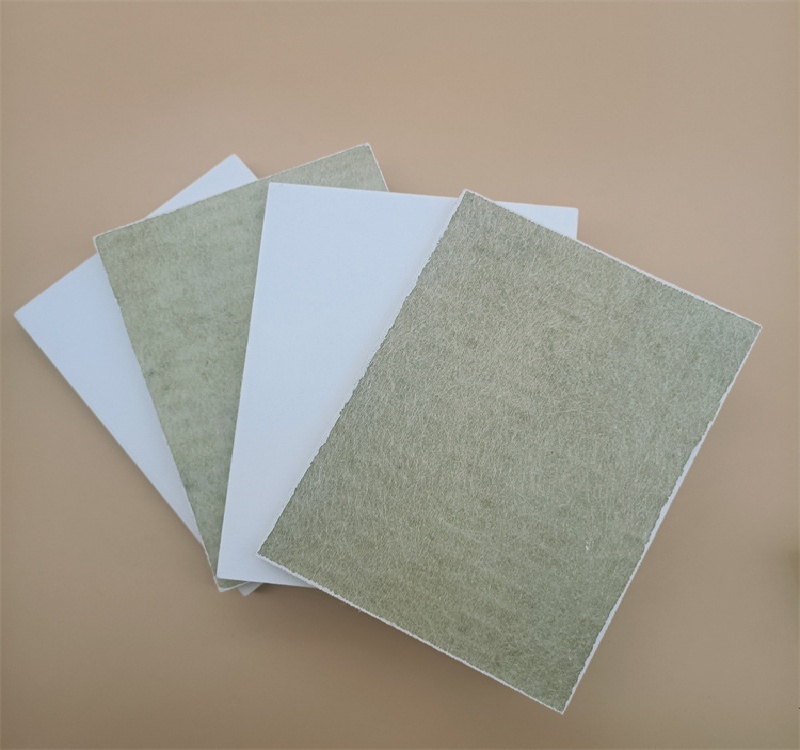

The full name of fiberglass ceiling is glass fiber ceiling. It is made from glass as the core material. After melting, drawing, and fiberization processes, it is mixed with appropriate adhesives, moisture – proof agents and other auxiliary materials, and then processed through pressing, curing, cutting and other techniques to form a sheet. The glass fiber component usually accounts for more than 70%. According to the differences in glass raw materials, it can be divided into non – alkaline fiberglass, medium – alkaline fiberglass, etc. Among them, non – alkaline fiberglass has stronger corrosion resistance and is more widely used in high – end scenarios.

1.2 Key Performance Characteristics

- Excellent acoustic performance: The interior of the fiberglass is composed of a porous fiber interwoven structure, which has outstanding absorption capacity for sound waves. The noise reduction coefficient (NRC) of conventional products can reach 0.5 – 0.8, and some high – end sound – absorbing products even have an NRC value exceeding 0.9. It can effectively improve the acoustic environment of the space and reduce echoes and noise interference.

- Lightweight and environmentally friendly: The density of the board is usually only 100 – 200 kg/m³, much lower than that of traditional materials such as stone and ceramic tiles, which can reduce the building’s load – bearing pressure; at the same time, the high – quality glass fiber ceiling does not contain harmful substances such as formaldehyde and benzene, meeting the national E0 – level environmental protection standard, with a combustion performance reaching A – level non – combustible, and having high safety in use.

- Excellent moisture – proof and weather resistance: The fiberglass ceiling treated with special moisture – proofing technology has a moisture absorption rate of less than 5%. When used in damp bathrooms, kitchens or underground spaces, it is unlikely to undergo deformation or mold growth; and it is resistant to acid and alkali corrosion, maintaining strong appearance stability over a long period of use.

- Decorative flexibility: Through surface coating, embossing, spraying and other processes, various appearance effects such as wood grain, stone texture, and solid colors can be achieved. It can also be made into perforated or hollow styles, balancing both acoustic functions and decorative requirements, and suitable for different decoration styles.

1.3 Applicable Scenarios

It is widely used in places with high requirements for acoustic environment and environmental protection, such as offices, meeting rooms, school classrooms, hospital consultation rooms, and shopping mall corridors; it can also be used for local ceiling decoration in family living rooms and bedrooms to enhance the comfort of the space.

2. Mineral Fiber Ceiling: A Cost – effective and Versatile Panel Material

2.1 Core Definition and Raw Material Composition

The mineral wool ceiling is a type of ceiling panel made from industrial slag (such as blast furnace slag and steel slag) as the main raw material, combined with a small amount of limestone, dolomite and other auxiliary materials. After being melted, centrifuged into fibers, and adding a bonding agent, it is then formed, dried, and cut. The proportion of slag in its composition usually exceeds 60%, and it is an environmentally friendly product that utilizes industrial waste slag for resource utilization.

2.2 Key Performance Characteristics

- Comprehensive cost – effectiveness: The raw materials are widely available and the cost is relatively low, which makes the price of mineral wool ceilings much lower than that of high – end fiberglass and rock wool products. At the same time, it has basic sound absorption and insulation properties and is suitable for large – scale engineering applications.

- Excellent thermal insulation and preservation properties: The porous structure formed by the interweaving of fibers results in a low thermal conductivity (typically ranging from 0.035 to 0.045 W/(m·K)), effectively reducing the transfer of heat between indoors and outdoors. This helps to enhance energy conservation in buildings, and is particularly suitable for public buildings in northern cold regions.

- Fire resistance performance is reliable: It inherently possesses non – combustibility properties and its combustion performance can reach Class A level. When exposed to fire, it does not release toxic gases and only undergoes slight contraction, allowing for more time for evacuation in case of a fire, meeting the fire safety standards for public buildings.

- Convenient processing and installation: The board has a relatively soft texture, making it easy to cut and drill. It can be flexibly adjusted according to the on – site dimensions. The use of a keel hoisting method ensures high installation efficiency, and it is also relatively convenient for later maintenance and replacement.

- Limitations: The moisture – proof performance is relatively weak. Unprocessed products are prone to absorb moisture and deform in high humidity environments, thus not suitable for damp areas such as bathrooms and kitchens; some mid – to – low – end products may have dust shedding issues, so it is recommended to choose high – quality brand products.

2.3 Applicable Scenarios

It is mainly used in factory workshops, warehouses, large supermarkets, underground garages, ordinary teaching buildings, economy hotels, etc., for large areas of spaces that are cost – sensitive and have low requirements for moisture prevention; it can also be used for the non – humid areas of northern residences, taking into account both insulation and decoration needs.

3. Rock wool ceiling: Special protective panels with high temperature resistance and fireproof properties

3.1 Core Definition and Raw Material Composition

Rock wool ceiling, also known as volcanic rock wool ceiling, is made from natural basalt, diabase and other volcanic rocks as the main raw materials, combined with a small amount of calcite, feldspar, etc. After being melted at high temperature (with the melting temperature reaching over 1500℃), centrifugally spun, and adding a special adhesive, it is then pressed and cured to form a special ceiling. The proportion of volcanic rock components exceeds 90%, and the fiber structure is more dense, with performance focusing more on high – temperature resistance and fire resistance.

3.2 Key Performance Characteristics

- Ultra – high fire resistance and high temperature tolerance: This is the core advantage of rock wool ceilings. Their continuous operating temperature can reach 600 – 800℃, and they can withstand temperatures above 1000℃ for a short period. The combustion performance is A – level non – combustible. When exposed to fire, there is no melting or dripping, and no toxic or harmful gases are released. It is the preferred material for places with extremely high fire protection requirements.

- Excellent sound insulation and heat insulation performance: The dense fiber structure enables it to not only absorb airborne sounds but also effectively block impact sounds. The sound insulation level can reach 35 – 45 dB. At the same time, the thermal conductivity is as low as 0.030 – 0.040 W/(m·K), and its heat insulation and insulation effect is superior to that of glass fiber and mineral wool.

- Stable mechanical properties: The density of the sheet material is relatively high (typically ranging from 200 to 300 kg/m³), with strong resistance to impact and deformation. It is unlikely to experience cracking or damage over a long period of use.

- Limitations: The weight is relatively heavy, which requires higher load – bearing capacity of the ceiling joists; The price is higher, far exceeding that of fiberglass and mineral wool ceilings; The decorative options are relatively limited, mostly in solid colors, and the cost of surface treatment processes is high.

3.3 Applicable Scenarios

It is mainly used in places with strict fire protection standards, such as stairwells of high – rise buildings, elevator shafts, power distribution rooms, laboratories, above – stage areas of theaters, data centers, etc.; it can also be used for industrial building ceilings in high – temperature environments, such as metallurgical workshops, boiler rooms, etc.

4. Comparison of Core Differences and Purchase Suggestions for the Three Options

4.1 Summary of Core Differences

| Comparison Dimension | Fiberglass Ceiling | Mineral Wool Ceiling | Rock Wool Ceiling |

|---|---|---|---|

| Core Raw Material | Glass | Industrial Slag | Basalt and Other Volcanic Rocks |

| Density (kg/m³) | 100 – 200 | 120 – 250 | 200 – 300 |

| Fire Resistance Rating | Class A Non-flammable | Class A Non-flammable | Class A Non-combustible (with superior heat resistance) |

| Sound Absorption Performance (NRC) | 0.5 – 0.9 | 0.4 – 0.7 | 0.5 – 0.8 |

| Moisture-proof Performance | Better (with moisture-proof treatment) | Generally (avoid high humidity) | Better (with dense structure to prevent moisture) |

| Price Range | Mid-to-high end ¥30-80/SQM | Economy type ¥15-40/SQM | High-end ¥80-200/SQM |

| Core Advantage |

|

|

|

4.2 Core Purchase Suggestions

- Prioritize clarifying the core requirements: If the focus is on acoustics and environmental protection, and the budget is moderate, choose fiberglass ceiling; if cost control is the priority and it is used in ordinary dry spaces, choose mineral wool ceiling; if the core requirement is fire resistance and high temperature tolerance, and the budget is sufficient, choose rock wool ceiling.

- Focus on key indicators: For environmental protection, review the report on formaldehyde emission. For fire resistance, confirm that the combustion performance is at the A level. For sound absorption, select products with the corresponding NRC value based on the space requirements. For damp environments, pay special attention to checking the moisture – proof performance parameters.

- Attach importance to product quality: Avoid purchasing low – priced inferior products. For fiberglass ceilings, pay attention to whether the surface is smooth and if there are any fibers falling off; for mineral wool ceilings, focus on the moisture – proof treatment process; for rock wool ceilings, make sure to confirm the purity of the raw materials and the fiber density, and ensure that the high – temperature resistance performance meets the standards.

- Matching installation conditions: Due to the heavy weight of rock wool ceilings, it is necessary to confirm the load – bearing capacity of the ceiling joists in advance and take reinforcement measures if necessary; before installing fiberglass and mineral wool ceilings, it is necessary to check the flatness of the base layer to ensure a good appearance after installation.

5. Summary

Although fiberglass, mineral wool, and rock wool ceiling panels all belong to fiber – based materials, they have distinct performance advantages and application boundaries due to their different raw material characteristics. The fiberglass ceiling panel, with “high sound absorption, environmental friendliness, and decorative properties” as its core competitiveness, is suitable for various spaces that require acoustic and aesthetic qualities; the mineral wool ceiling panel, based on “high cost – effectiveness”, has become an economical choice for large – scale ordinary spaces; the rock wool ceiling panel, with its “extreme fire resistance and high temperature resistance” characteristics, is irreplaceable in special protection scenarios. In actual selection, it is necessary to combine core requirements such as space function, budget, fire prevention, and moisture resistance, and precisely match the product characteristics to achieve a perfect unity of decorative effect and functional use.